NIT researchers develop eco-friendly process to remove pharmaceutical pollutants from wastewater

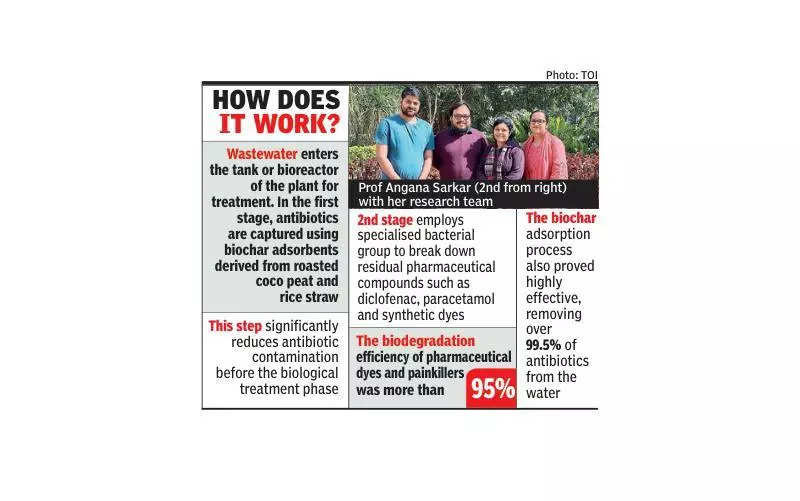

Bhubaneswar/Rourkela: Researchers at the National Institute of Technology (NIT) Rourkela developed a process to remove pharmaceutical pollutants from wastewater. The process can filter out antibiotics, non-steroidal anti-inflammatory drugs (NSAIDs), and synthetic dyes, among others, through adsorption and biodegradation methods.

This research was published in the Journal of Water Process Engineering, a peer-reviewed research journal. The paper was co-authored by Angana Sarkar, along with her research team Kasturi Poddar, Debapriya Sarkar, and Pritam Bajirao Patil.

Sarkar, an associate professor of NIT Rourkela’s biotechnology and medical engineering department, said they made a prototype to remove pharmaceutical pollutants from wastewater. “It can be scaled up for business purposes. The size of the plant can be decided by calculating the amount of wastewater generation from industry and other facilities,” she added.

She said they use two stages to remove the pharmaceutical contaminants from the wastewater. “First, we use agricultural residues like paddy straw and coco peat to filter the antibiotics out of the wastewater. Later, we use bacteria to treat the remaining pollutants. These are not harmful bacteria. The whole process is eco-friendly,” she added.

The researchers said these pollutants come through domestic sewage, hospital waste, pharmaceutical industries, and livestock farming. “If it enters directly into water bodies without treatment, it can pose significant risks to humans and aquatic organisms. These endocrine-disrupting chemicals interfere with hormonal systems, causing acute health issues,” she added.

She said antibiotics in wastewater are particularly concerning, as a large amount is excreted unchanged, contributing to the rise of antibiotic-resistant bacteria. “Conventional wastewater treatment methods struggle to remove these contaminants, allowing them to persist in rivers, lakes, and groundwater. To address these challenges, we developed this integrated treatment process that effectively removes pharmaceutical pollutants through a two-stage approach,” she added.

Sarkar said this new system efficiently removed various pharmaceutical pollutants. “This process is non-toxic, sustainable, and cost-effective, and it can be scaled up in the near future in collaboration with the pharmaceutical industries,” she added.

The treatment costs about Rs 2.6 per litre, and it can be further reduced by process optimisation and integrating this system as a tertiary step in existing treatments, said the researchers. “Future studies will focus on recovering and purifying adsorbed antibiotics from biochar, offering a valuable resource that could generate profit and reduce pharmaceutical manufacturing costs. This recovery could make medicines more affordable for underserved communities. Also, antibiotic-free biochar can be repurposed as fertiliser, ensuring a zero-waste process,” she added.

This research was published in the Journal of Water Process Engineering, a peer-reviewed research journal. The paper was co-authored by Angana Sarkar, along with her research team Kasturi Poddar, Debapriya Sarkar, and Pritam Bajirao Patil.

Sarkar, an associate professor of NIT Rourkela’s biotechnology and medical engineering department, said they made a prototype to remove pharmaceutical pollutants from wastewater. “It can be scaled up for business purposes. The size of the plant can be decided by calculating the amount of wastewater generation from industry and other facilities,” she added.

She said they use two stages to remove the pharmaceutical contaminants from the wastewater. “First, we use agricultural residues like paddy straw and coco peat to filter the antibiotics out of the wastewater. Later, we use bacteria to treat the remaining pollutants. These are not harmful bacteria. The whole process is eco-friendly,” she added.

The researchers said these pollutants come through domestic sewage, hospital waste, pharmaceutical industries, and livestock farming. “If it enters directly into water bodies without treatment, it can pose significant risks to humans and aquatic organisms. These endocrine-disrupting chemicals interfere with hormonal systems, causing acute health issues,” she added.

She said antibiotics in wastewater are particularly concerning, as a large amount is excreted unchanged, contributing to the rise of antibiotic-resistant bacteria. “Conventional wastewater treatment methods struggle to remove these contaminants, allowing them to persist in rivers, lakes, and groundwater. To address these challenges, we developed this integrated treatment process that effectively removes pharmaceutical pollutants through a two-stage approach,” she added.

Sarkar said this new system efficiently removed various pharmaceutical pollutants. “This process is non-toxic, sustainable, and cost-effective, and it can be scaled up in the near future in collaboration with the pharmaceutical industries,” she added.

The treatment costs about Rs 2.6 per litre, and it can be further reduced by process optimisation and integrating this system as a tertiary step in existing treatments, said the researchers. “Future studies will focus on recovering and purifying adsorbed antibiotics from biochar, offering a valuable resource that could generate profit and reduce pharmaceutical manufacturing costs. This recovery could make medicines more affordable for underserved communities. Also, antibiotic-free biochar can be repurposed as fertiliser, ensuring a zero-waste process,” she added.