Thousands of tonnes of wool produced, but 90% wasted

BENGALURU: Despite India’s vast wool production, experts say the industry remains underdeveloped, with most of the wool going to waste even while imports surge.

The challenge, they say, is a lack of research and a structured supply chain to ensure high-quality wool reaches the market.

Unlike in other countries where sheep are raised on large farms, Indian wool comes from nomadic pastoralists, making standardisation a significant hurdle.

“We have 44 different breeds of sheep across diverse landscapes — from Ladakh to the arid regions and the Himalayas to the Deccan. Yet only 5% to 7% of this wool is used. The rest is simply discarded,” said Sandeep Virmani, president, Sahajeevan, an organisation working to empower self-sustaining communities.

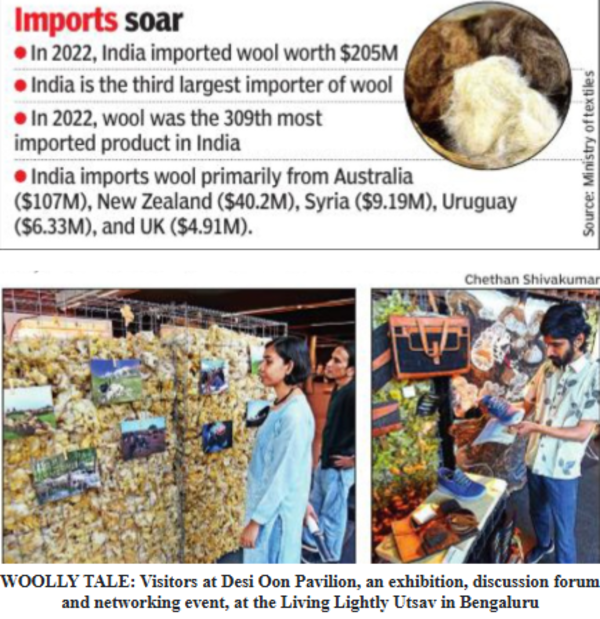

Speaking at Desi Oon Pavilion, an exhibition, discussion forum and networking event organised as part of Living Lightly Utsav (a Deccani Pastoralism festival), Viramni highlighted the difficulties in collecting and processing wool from constantly migrating flocks.

“It is pastoralists who own most of the sheep in the country,” he said. “Shepherds keep moving with their flock. So how do you collect sheep wool? How do you shear it, clean it, bring it to the market, and then make it available for processing?” He pointed out that research on Indian wool is still in a nascent stage and though the govt has begun supporting procurement centres, more work is needed.

Shishir Tyagi, deputy director, Wool Research Association, said India produced 34,000 tonnes of wool in 2023-24, but much of it remains underutilised due to quality issues. “Indian wool is coarser — some of it is used in carpets, but a significant portion is wasted. A major challenge is micron size and fibre length. Wool is often sheared too soon, sometimes at just half an inch, when it needs to be at least 1.5 inches for processing,” he said.

The association has proposed setting up a pro cessing centre under Karnataka Sheep and Wool Development Board to improve wool washing and preparation for industry use. Potential applications are vast, especially in temperaturecontrolled industries.

“India is a major pharmaceutical producer, and vaccine storage requires insulation. Indian wool could fill this gap,” said GS Bhati, executive director, Central Wool Development Board. But the industry faces another barrier: A lack of scientific data to validate its use.

“When we approached ISRO and the scientific adviser to the PM about using wool for insulation, they asked for research-backed data. That’s a crucial step we need to address,” Bhati said.